TDK’s Cores and USM’s Ready Made Impeders for High-frequency Tube Welding

Ferrite impeder cores of TDK Corp. (Japan) for a high-efficiency process of high-frequency tube welding and assembly impeders made on these cores.

LEPCOS Company is an exclusive distributor of USM Company (Italy) in Russia. More than 25 years, USM Company is a world-wide leading supplier of specialized consumable materials and mechanical equipment for production of steel tubes by high-frequency welding.

USM company implemented in Europe specialized ferrite materials made by TDK (Japan); these materials are of epoch event importance and are specially developed for high-frequency tube welding as a replacement of previously used ineffective cores made of ferrite’s antenna materials.

In cooperation with USM, LEPCOS Company offers to domestic manufacturers of tubes produced by high-frequency welding method, advanced complex technological solutions corresponding with requirements of XXI century.

Advantage of specialized ferrite materials offered by us and of technological solutions specially developed to optimize a high-frequency welding process, is a considerable decrease of hidden production costs due to:

Significant electrical energy saving due to considerable reduction of anode current value or to considerable increase of technological line speed with preservation of current’s value simultaneously improving a quality of welding seam owing to increase of welding process efficiency and to decrease of losses in using magnetic materials.

Significant life time increase of cores and assembly impeders offered by us for tube welding what eliminates a necessity of frequent expensive preventive stop of whole technological line.

Products

Ferrite cores TDK for high-frequency tube welding ZRS, ZRSH, ZR, ZRH-configured

Ferrite cores TDK for high-frequency tube welding ZRS, ZRSH, ZR, ZRH-configured

Standard Series of Assembly Impeders Through Flow

Standard Series of Assembly Impeders Through Flow

Standard Series of Assembly Impeders Return Flow

Standard Series of Assembly Impeders Return Flow

Copper Inductance Coils for High-frequency Tube Welding

Copper Inductance Coils for High-frequency Tube Welding

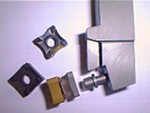

Carbide Cutting Inserts and Holders for Outside Tube Scarfing

Carbide Cutting Inserts and Holders for Outside Tube Scarfing

Saws and guillotine’s blades for tube cutting

Saws and guillotine’s blades for tube cutting

Complete catalogue (in .pdf format) of equipment and materials for high-frequency tube welding you may download in section Our catalogues.

Complete catalogue (in .pdf format) of equipment and materials for high-frequency tube welding you may download in section Our catalogues.

Additional Information

First of all, we recommend you to examine the description of high-frequency tube welding process.

The best method to prove an economical efficiency of your enterprise is to perform a cycle of practical tests. We are ready to provide you with all samples of products that would be necessary for this purpose.

If you have any problems with choice of standard sizes of ferrite cores and assembly impeders that are necessary for your application or with selection of materials for their casings, be pleased to fill in technical Questionary (doc) (ru).Depending on a specifics of your production and based on data about steel tube issued by you and about type of used generator, LEPCOS Co. in cooperation with USM specialists will help you in choice of optimum solutions and also will calculate and make an impeder that will be most effective for your application.