Microwave ferrites Temex-Ceramics

- At the expense of high specific electrical resistivity (ρ >106 Ом·sm) ferrites are characterised by low dielectric losses at high frequencies tgδ=10-2÷10-4).

- Dielectric permittivity ε' (about 10-15)

- Thermal stability in a wide temperature range

- The high activity is being determined by the value of minimal bias which is essential for required nominal parameters providing.

- Saturation magnetization, M s; 4πMs (400-5000 G)

- The width of resonance curve 2ΔH is one of the main parameters characterising properties of ferrites applied in high-frequency band. The yttrium-iron monocrystals exhibit the minimal value 2ΔH =0.3-0.5 Oe. The width of resonanse curve of polycrystalline ferrites varies from 30...40 to 800-1000 Oe.

The technical performance of devices on the base of ferrites mainly depends on operating principle, application, frequency band and power level. For many years Temex-Ceramics (1971, Bordeaux/France) is one of the world leaders in the field of high frequency materials development and manufacturing. In june 2012 Temex-Ceramics was introduced in Exxelia Group membership. This is a group of companies, supplying electronic parts for different industry fileds. The sales are being realized all over the world by officical distributors in Italy, Eastern Europe, Russia, India, Korea and others.

In 2008 "Lepcos" got a status of Temex-Ceramics official distributor.

Temex-Ceramics Ferrites can be successfully applied in circulators, isolators, phase-shifters, choppers and others.

| Application | Required characteristics | recommendations for materials choosing |

| Circulators of low power level | Low inserted losses,compactability, a wide frequency band, a wide nominal temperature range, high radiation directivity | The width of ferromagnetic resonance curve (2ΔH; ΔH eff) - minimal values; Dielectric permeability(ε') maximal value; Saturation magnetization (M s ) is determined in accordance with predermined frequency; Temperature coefficient(α) is minimal |

|---|---|---|

| Circulators of high power level | The power stability, low inserted lossses , thermal stability | The value characterising the width of spin wave line (ΔH k) must be high ; ΔH eff and ΔH should be close to the the value of ΔH k |

| Resonance-type isolator (working range - up to resonance) | low inserted losses, narrow -width frequency band | Effective width of resonance curve ΔH eff minimal; M s corresponds to frequency |

General characteristics of Temex-Ceramics materials are listed in the table below.

| Crystal structure | Temex-Ceramics part number | chemical composition | Recommended frequency band | Thermal stability | Power stability | Magnetic losses |

| Garnet | Y1xx | Y-Gd | 1.55-10.90 GHz | ** | * | * |

| Garnet | Y2xx | CVG | 1.55-10.90 GHz | ** | * | *** |

| Garnet | Y3xx | Y-Al | 0.34-6.20 GHz | * | * | ** |

| Garnet | Y4xxx | Y-Al | 1.55-6.20GHz | *** | ** | ** |

| Гранат | Y7xx | Y-Gd-Al | 0.34-6.20 GHz | * | ** | * |

| Garnet | Y9xx | Y-Gd-Al with Co additive | 0.34-10.90 GHz | ** | *** | * |

| Garnet | Dx | Y-Gd-Al with Dy additive | 0.34-10.90 GHz | ** | *** | * |

| Spinel | Uxx | Mn-Mg | 1.55-36 GHz | * | * | ** |

| Spinel | Axxx | Li | 6.20-40 GHz | *** | * | *** |

| Spinel | Nxxx | Ni | 1.55-40 GHz | *** | *** | * |

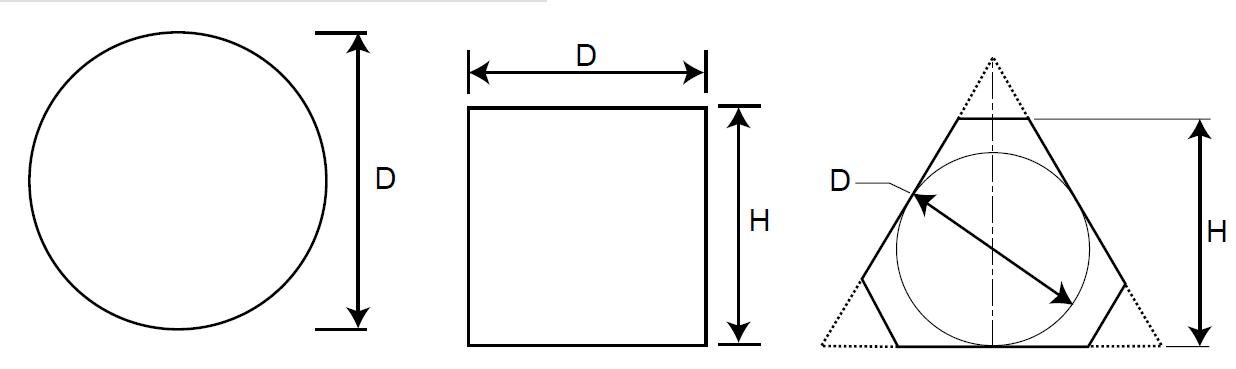

Configurations

| Disk | Diameter: 1-55 mm |

|---|---|

| Plates | maximal size: 50.8 х 50.8 mm thickness: 0.5-3 mm |

| Triangles Rods | max diameter: 12mm max length: 90 mm |

| Composition | Ferrites and dielectric materials |

| Oredering Code | Configuration |

| D | Disk |

| T | Triangle |

| S | Plate |

Dimensional allowance for all configurations are listed below.

| Ordering code | Dimensional allowance (mm) | Dimensional allowance (inch) |

| Z | ±0.200 | ±0.008 |

| Y | ±0.150 | ±0.006 |

| X | ±0.100 | ±0.004 |

| W | ±0.050 | ±0.002 |

| V | ±0.025 | ±0.001 |

TEMEX-CERAMICS ferrite materials

Тemex-Ceramics manufactures ferrites on the base of compounds with garnet and spinel structures. Yttrium-iron garnets are applied for production of different high-frequency devices operating in low border of high-frequency band. The great interest to ferrites with garnet structure, particularly, to yttrium garnet is explained by narrow line of ferromagnetic resonance absorption. Such materials are also characterised by small magnetic losses; relatively high magnetization; high thermalstability.Often ions of Cobalt and Rare-earth ions (Dy), (Gd) are introduced to materilas structure in order to improve material characteristics for increasing of ferrite stability to Power.

Тemex-Ceramics manufactures ferrites on the base of compounds with garnet and spinel structures. Yttrium-iron garnets are applied for production of different high-frequency devices operating in low border of high-frequency band. The great interest to ferrites with garnet structure, particularly, to yttrium garnet is explained by narrow line of ferromagnetic resonance absorption. Such materials are also characterised by small magnetic losses; relatively high magnetization; high thermalstability.Often ions of Cobalt and Rare-earth ions (Dy), (Gd) are introduced to materilas structure in order to improve material characteristics for increasing of ferrite stability to Power.