Due to the large number of DC consumers, particularly, various electronic devices and electric motors, the achieving of high-qualified energy is the key task both for large enterprises and trading companies.

As long as sufficient losses in electrical networks influence greatly on the working efficiency and in some cases can lead to a breakdown it is very important to decrease the contribution of different negative factors influencing on the effectiveness of different devices operation.

Due to the large number of DC consumers, particularly, various electronic devices and electric motors, the achieving of high-qualified energy is the key task both for large enterprises and trading companies.

As long as sufficient losses in electrical networks influence greatly on the working efficiency and in some cases can lead to a breakdown it is very important to decrease the contribution of different negative factors influencing on the effectiveness of different devices operation.

The appearance of reactive power leads to additional load which influences on network. In this regard Power Factor Correction systems are applied in order to decrease current an electrical circuit and parasite active losses in conductors.

The application of PFC components is interestiong for static power supply unit designing. The most simple solution of decreasing of reactive power can be the choise of passive circuit in order to increase of power factor representing a

choke located between electrical power unit and high voltage capacitor.

The application of such components in the PFC circuits allows:

- to smooth the current impulse

- to increase the power factor

- to unload the network

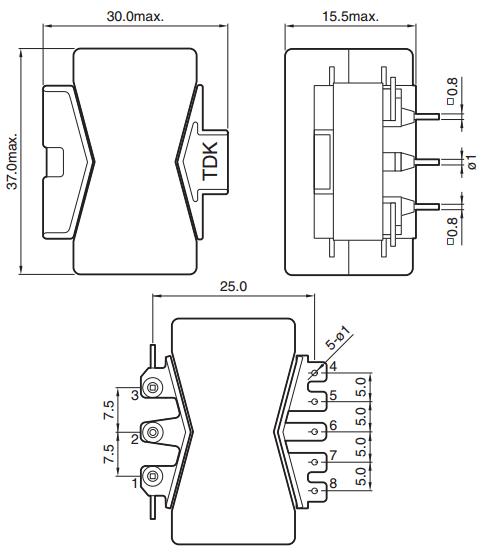

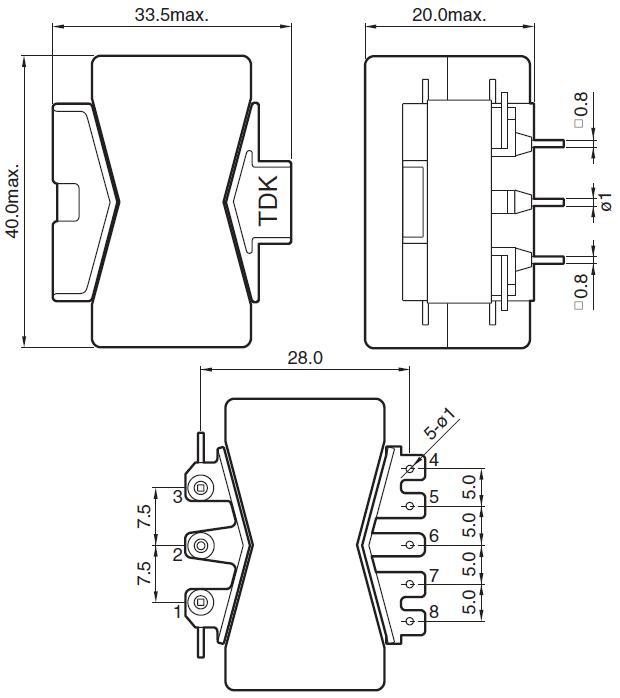

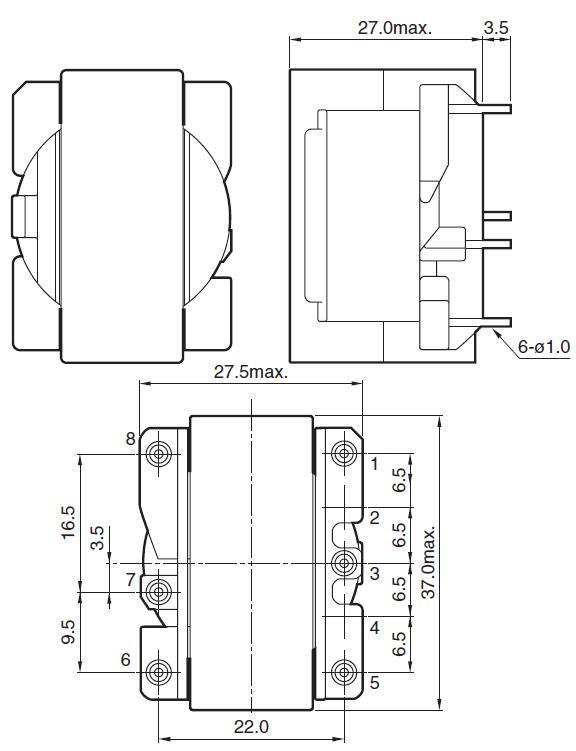

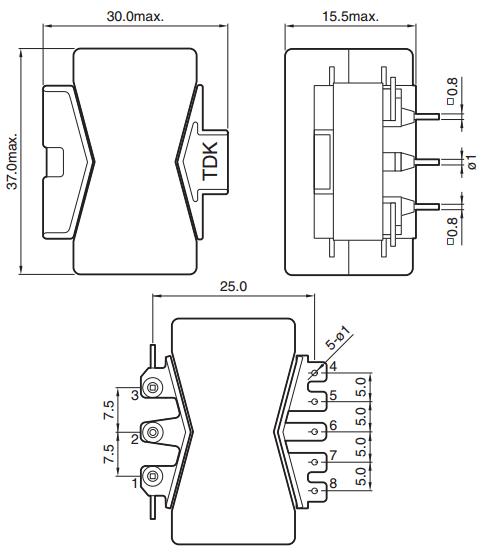

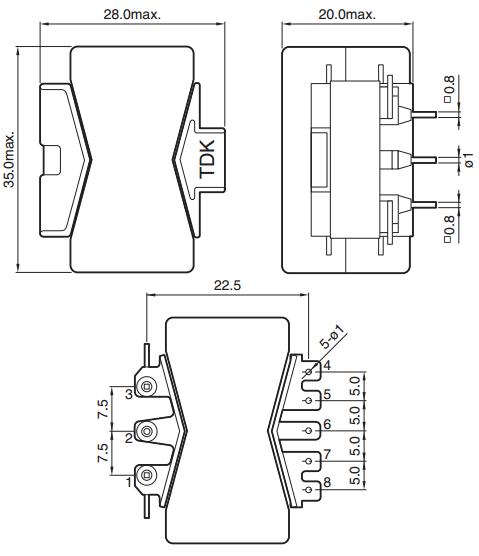

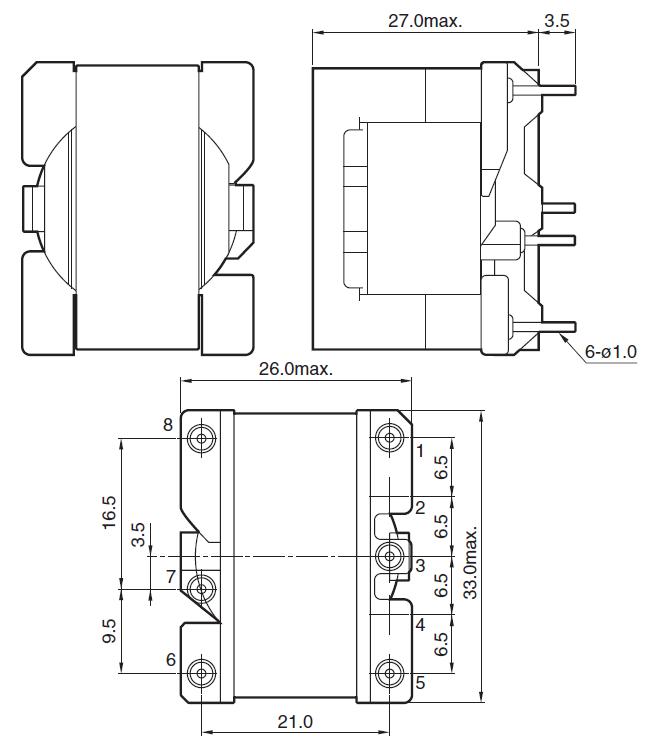

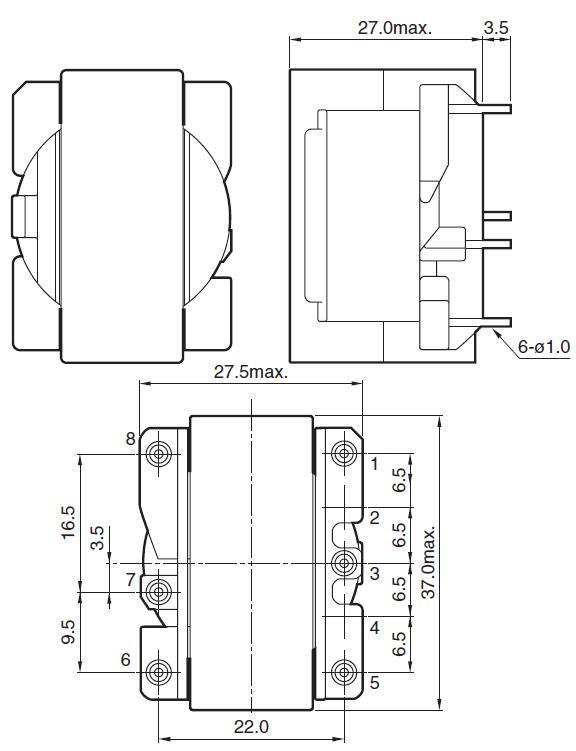

At present time among chokes produced by different manufacturers one can note TDK pfc chokes. Such components are characterised by high reliability, high efficiency factor, small sizes and at the same time ability to pass current oa f bilg value. Particularly, the components height varies from 15.5...27 mm. Particularly, the height of components vary in the range 15.6...27mm. PFC chokes can be applied in Audio- and Video Systems and computer networks, telecommunications, digital technique, LED equipment and others.

Main characteristics of PFC chokes are represented in the table.

At present time among chokes produced by different manufacturers one can note TDK pfc chokes. Such components are characterised by high reliability, high efficiency factor, small sizes and at the same time ability to pass current oa f bilg value. Particularly, the components height varies from 15.5...27 mm. Particularly, the height of components vary in the range 15.6...27mm. PFC chokes can be applied in Audio- and Video Systems and computer networks, telecommunications, digital technique, LED equipment and others.

Main characteristics of PFC chokes are represented in the table.

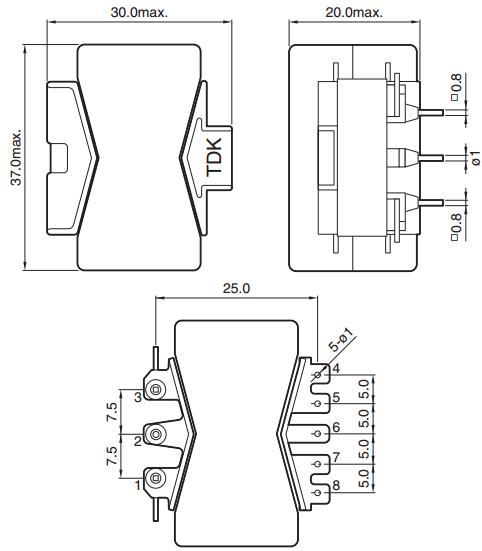

| Technical characterstics of PFC3514QM series |

|---|

| Ordering code

| Mounting design

| fmin, KHz

| Output power, W

| L, µH

| I nom. peak, А

| Turn ratio

| Drawing

| Documentation

|

| PFC3514QM-351K04B-00

| Through hole

| 65

| 100

| 350

| 3,7

| 10,0

|   |

|

| PFC3514QM-281K05B-00

| Through hole

| 65

| 125

| 280

| 4,6

| 9,8

|

| PFC3514QM-231K06B-00

| Through hole

| 65

| 150

| 230

| 5,5

| 9,6

|

| Technical characteristics of PFC3318QM series |

|---|

| PFC3318QM-601K03B-00

| Through hole

| 50

| 75

| 600

| 2,8

| 9,0

|   |

|

| PFC3318QM-601K03E-00

| Through hole

| 50

| 75

| 600

| 2,8

| 9,6

|

| PFC3318QM-451K04B-00

| Through hole

| 50

| 100

| 450

| 3,7

| 9,0

|

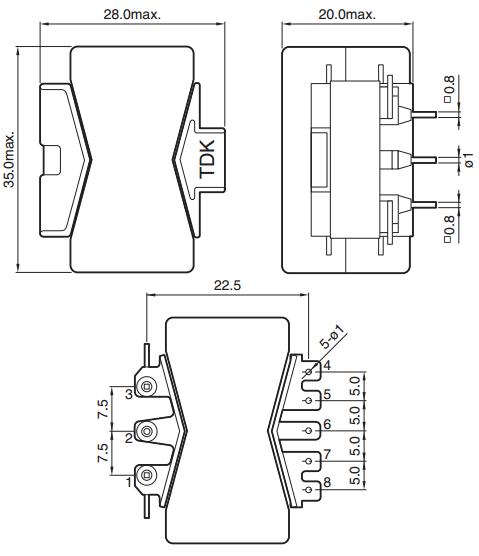

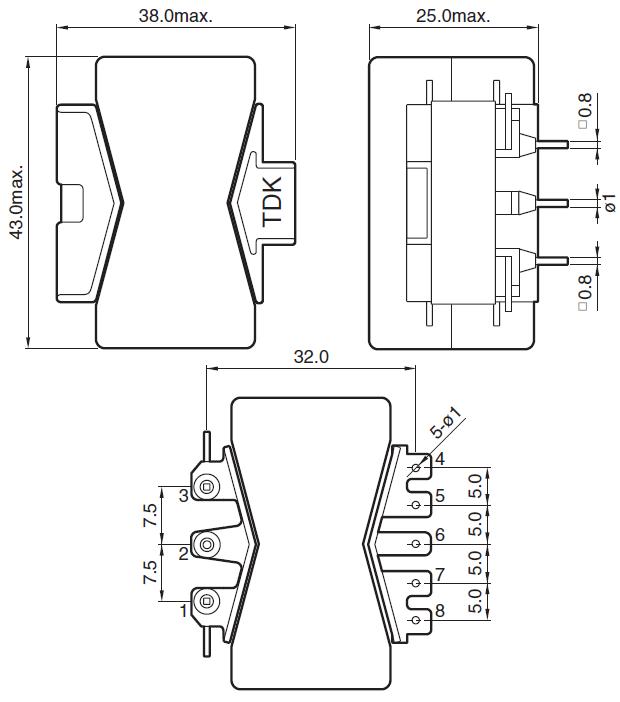

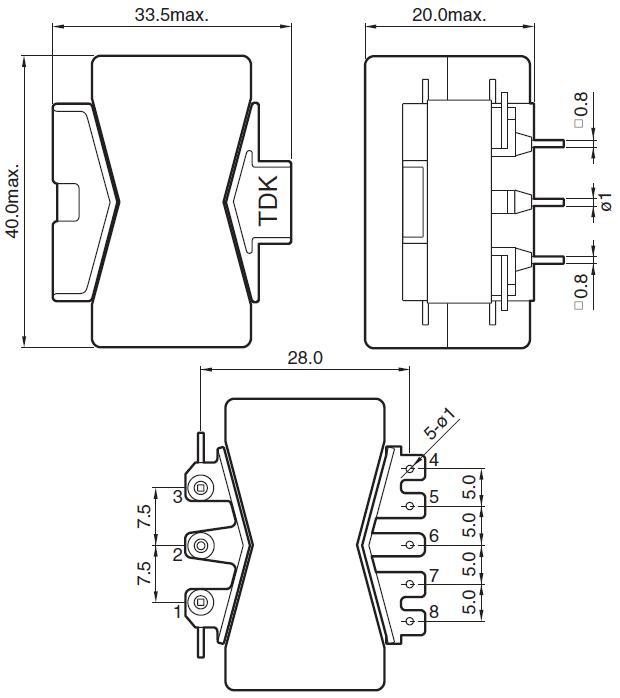

| Technical characteristics of PFC3519QM series |

|---|

| PFC3519QM-451K04E-00

| Through hole

| 50

| 100

| 450

| 3,7

| 10,0

|   |

|

| PFC3519QM-301K06B-00

| Through hole

| 50

| 150

| 300

| 5,5

| 9,8

|

| PFC3519QM-231K07B-00

| Through hole

| 50

| 200

| 230

| 7,4

| 9,6

|

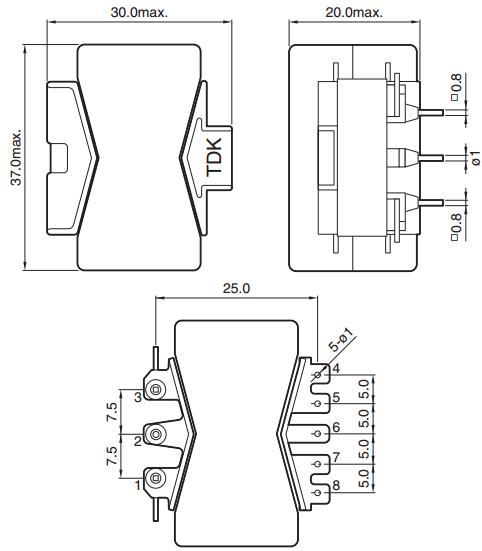

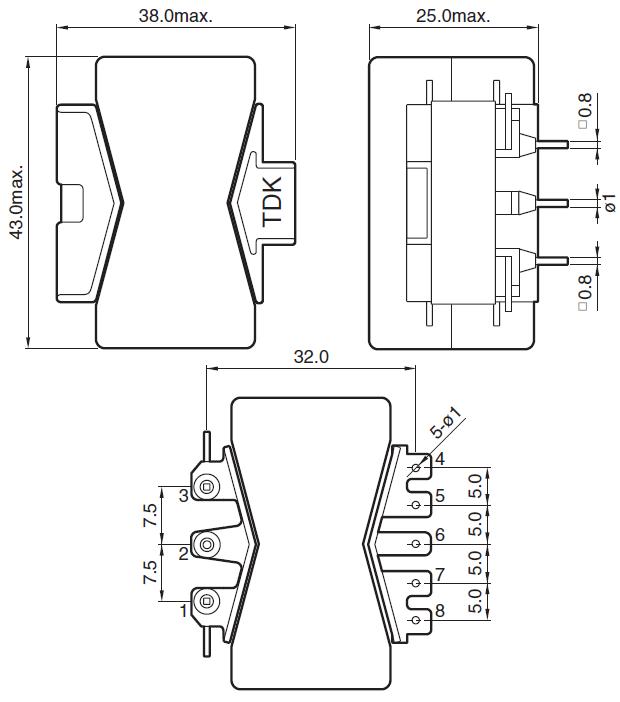

| Technical characteristics of PFC3819QM series |

|---|

| PFC3819QM-301K06E-00

| Through hole

| 50

| 150

| 300

| 5,5

| 9,8

|   |

|

| PFC3819QM-231K07D-00

| Through hole

| 50

| 200

| 230

| 7,4

| 9,6

|

| PFC3819QM-181K09B-00

| Through hole

| 50

| 250

| 180

| 8,8

| 9,5

|

| PFC3819QM-151K11B-00

| Through hole

| 50

| 300

| 150

| 11,1

| 9,8

|

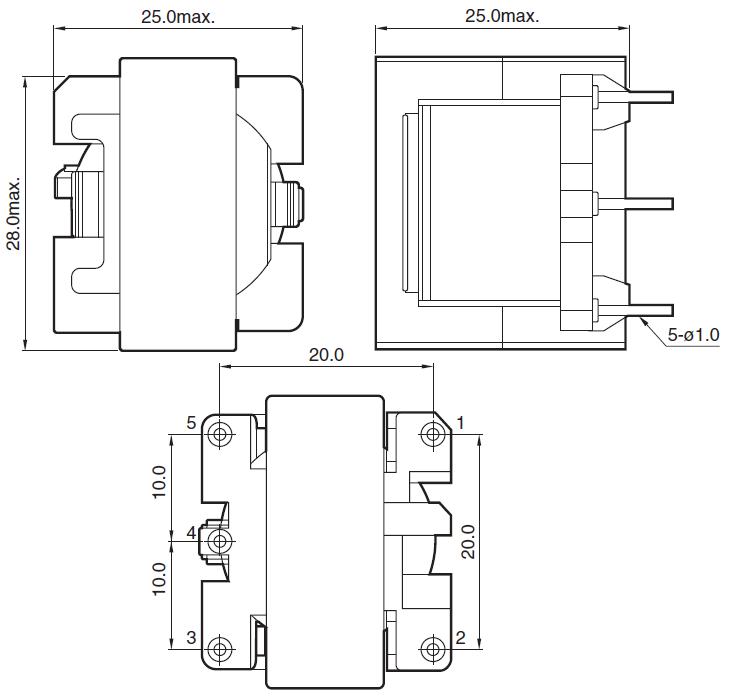

| Technical characteristics of PFC4124QM series |

|---|

| PFC4124QM-181K09D-00

| Through hole

| 50

| 250

| 180

| 8,8

| 9,5

|   |

|

| PFC4124QM-151K11D-00

| Through hole

| 50

| 300

| 150

| 11,1

| 9,8

|

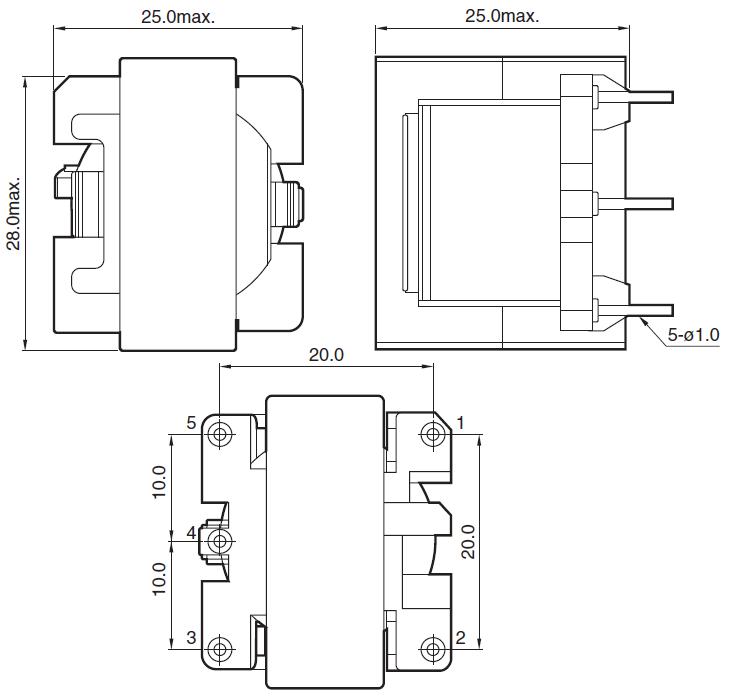

| Technical characteristics of PFC2723ER series |

|---|

| PFC2723ER-601K02B-00

| Through hole

| 50

| 75

| 600

| 2,4

| 9,8

|   |

|

| PFC2723ER-421K03B-00

| Through hole

| 50

| 100

| 420

| 3,4

| 10,8

|

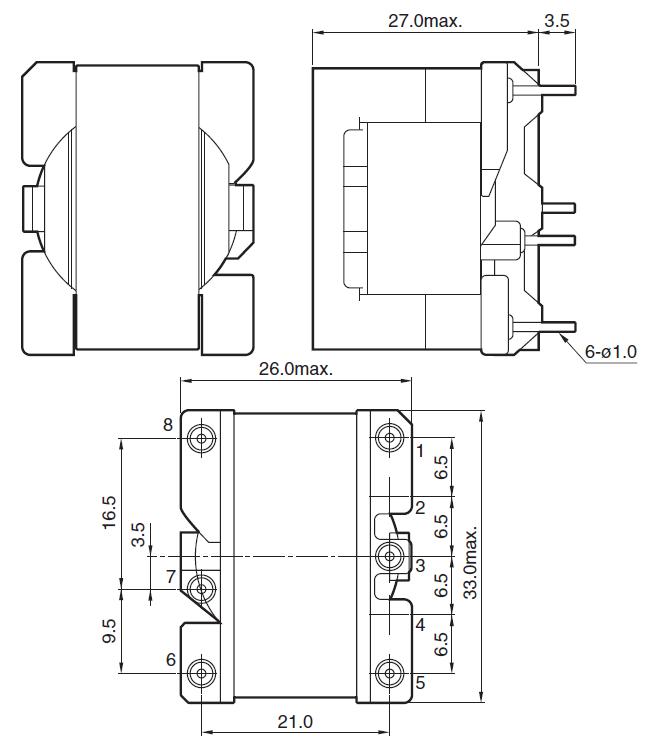

| Techical characteristics of PFC3125ER series |

|---|

| PFC3125ER-451K03E-00

| Through hole

| 50

| 100

| 450

| 2,7

| 10,0

|   |

|

| PFC3125ER-301K05B-00

| Through hole

| 50

| 100

| 450

| 2,7

| 10,0

|

| PFC3125ER-231K06B-00

| Through hole

| 50

| 200

| 230

| 6,4

| 9,0

|

| Technical characteristics of PFC3525ER series |

|---|

| PFC3525ER-301K04E-00

| Through hole

| 50

| 150

| 300

| 4,1

| 10,4

|   |

|

| PFC3525ER-231K06E-00

| Through hole

| 50

| 200

| 225

| 5,6

| 10,0

|

| PFC3525ER-181K09B-00

| Through hole

| 50

| 250

| 180

| 9,5

| 10,5

|

Additional information

For searching by characteristics one can use

program at the producer's website