Amorphous and nanocrystalline Cores

The improvement of electromagnetic characteristics of materials used for coils manufacturing is one of important and emerged areas in modern electronics. Among such improvement methods one can note the creation of new composite materials based on soft magnetic alloys. These material are widely applied in matching, high-frequency and power transformers, as well as in current sensors and represent complicated multicomponent system. A chemical composition of soft magnetic alloys with two -phase structure is

Fe73,5CuNb3Si13,5B9.

Ribbons with amorphous structure characterized by the absence of a long-range order in atoms arrangement are obtained from a material melting by spinning or a flat jet methods.

The melt falling from the slot of the nozzle on the rotating drum surface, is being cooled, then it solidifies, thus forming a ribbon with an amorphous structure. The ribbon's thickness is ordinary 25 ± 5 µm. In order to achieve the required magnetic properties at the second technological stage, an amorphous ribbon is thermally being treated at high temperatures. As a result of operation carried out at a temperature of not less than 600 °C, the partial crystallization occurs and nucleating centers of the iron silicide phase (α-Fe-Si) are formed.

The improvement of electromagnetic characteristics of materials used for coils manufacturing is one of important and emerged areas in modern electronics. Among such improvement methods one can note the creation of new composite materials based on soft magnetic alloys. These material are widely applied in matching, high-frequency and power transformers, as well as in current sensors and represent complicated multicomponent system. A chemical composition of soft magnetic alloys with two -phase structure is

Fe73,5CuNb3Si13,5B9.

Ribbons with amorphous structure characterized by the absence of a long-range order in atoms arrangement are obtained from a material melting by spinning or a flat jet methods.

The melt falling from the slot of the nozzle on the rotating drum surface, is being cooled, then it solidifies, thus forming a ribbon with an amorphous structure. The ribbon's thickness is ordinary 25 ± 5 µm. In order to achieve the required magnetic properties at the second technological stage, an amorphous ribbon is thermally being treated at high temperatures. As a result of operation carried out at a temperature of not less than 600 °C, the partial crystallization occurs and nucleating centers of the iron silicide phase (α-Fe-Si) are formed.

Thus, a distinctive feature of such materials is the presence in their composition of both the amorphous component and a certain fraction of the crystalline phase. The crystallites size in such alloys is 10–20 nm; therefore, these materials are often called nanocrystalline. Depending on the composition of the alloy, the percentage phase ratio may vary. As a rule, the proportion of the crystalline structure prevails.

The introduction of such addings as Si and B into alloys content allows an amorphous structure forming, while niobium ions inhibit the growth of grains at higher operating temperatures. In addition to niobium ions, additives of other metals, such as Zr, Mo, Hf, Ta, W can be used to reduce crystallites size. The introduction of copper ions leads to the formation of a large number of crystallization centers.

To improve the magnetic characteristics and significantly reduce the magnetostriction, a partial removing of iron atoms with aluminum is being carried out. Moreover, due to the distribution of nanoscale crystalline granules in the amorphous matrix in such alloys: very high values of magnetic permeability, a small values of coercive force , and the saturation induction (Bs) is 0.8 ... 1.2 T (Bs) are achieved.

Cores on the base of nanocrystalline material NANOPERM® produced by Magnetec (Germany)

Magnetec company founded in 1984 specializes in manufacturing of cores and chokes on the base of a thin ribbon consisting of nanocrystalline Fe-doped material called as NANOPERM®.

The high technical level of plants situated in Hungary, India and China provides a combination extremely high quality and acceptable prices.

Nanocrystalline cores

EMC series

These products ensure EMC (Electromagnetic Compatibility). For magnetic circuits of switching-mode power supplies and current transformers.

LM series cores

For application in EMC filters with a large amount of asymmetrical interference currents.

Coolblue series cores

Coolblue series cores

Nanocrystalline cores for manufacturing of EMC filters with a large value of impedance, transformers with low losses, for a defence of motors and generators from peak voltage and current surges.

LC series cores

LC series cores

Low-cost nanocrystalline NANOPERM cores for small-sized common mode chokes of EMI filters.

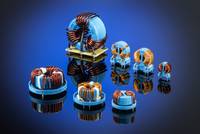

Chokes on the base of nanocrystalline cores

2-fold common-mode chokes for interference suppression

2-fold common-mode chokes for interference suppression

3-fold common-mode chokes

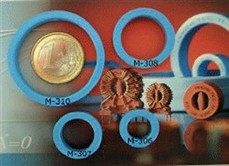

Toroidal amorphous and nanocrystalline MSTATOR cores

At the present moment MSTATOR produces ribbons on the base of amorphous and nanocrystalline AMAG alloys with a width from 1 to 30 mm and a thickness from 15 to 30 microns, toroidal magnetic cores, as well as final electromagnetic components. All products meet modern European and North American standards. More information about the manufactured magnetic cores and MSTATOR alloys properties one can found in following web-site pages:

"Toroidal amorphous and nanocrystalline MSTATOR cores»"

"Characteristics of amorphous and nanocrystalline AMAG alloys."