Noise Suppression Sheet "Flexield" IFL Series

What is the noise suppression sheet "Flexield"?

With electronic devices such as smartphones and tablets becoming increasingly more compact, thinner, and multi-functional, a large number of electronic components are mounted on the circuit board with high density, and therefore, suppression of noise emitted by the ICs and cables is becoming increasingly important. Since it is difficult to estimate this noise emission at the design stage, there are an increasing number of cases in which measures must be taken to suppress noise in the manufacturing stage.

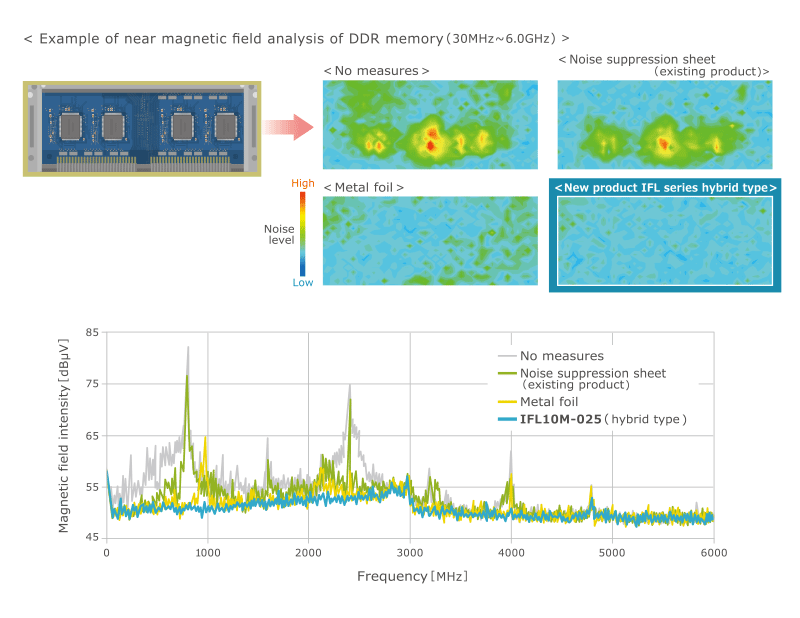

"Flexield", which is the noise suppression sheet from TDK (referred to simply as Flexield below) is a magnetic shielding material made by mixing finely powdered soft magnetic metal (flat powder) with plastic, and processing it into a flexible sheet. By pasting it on sources of noise emission, or pasting it in locations which are vulnerable to noise emission, it is extremely effective in noise suppression. It is easy to punch and cut, and can be processed into various shapes, and since it is flexible, it can even be used on curved surfaces and flexible cables (FPC/FFC) (Figure 1).

Figure 1: Example of the punching process of Flexield and examples of its uses

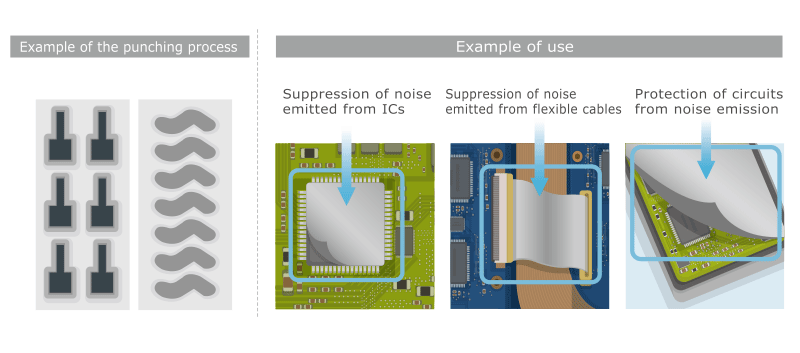

Structure of Flexield

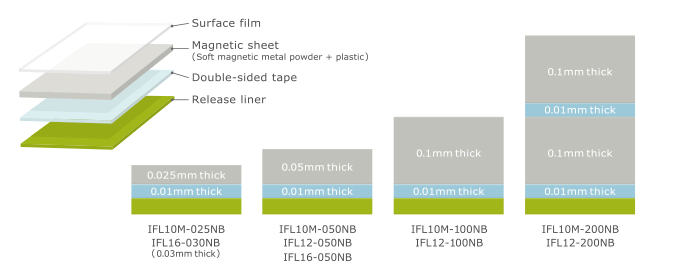

As shown in Figure 2, Flexield from TDK consists of the surface film, a magnetic sheet formed from soft magnetic metal powder mixed with plastic, double-sided tape, and release liner. The product is available both in roll form and in sheet form, and various products with thickness ranging from 0.025 mm to 0.2 mm are offered as the IFL series. You can also opt for double-sided tape depending on the use. In addition, we have also added the new product to our product range (described later). This is a hybrid-type product with a metal layer which has a much higher noise suppression effect.

Figure 2 Structure of Flexield and forms of the product

Main features and applications of Flexield

The main features and applications of Flexield are listed below.

- Since its material is made of soft magnetic metals with high permeability as materials, it is highly effective in suppressing noise emission.

- Since it is thin, it can be installed even in tiny gaps.

- Since it is a flexible sheet, it does not break upon impact.

- It can be processed into various shapes, and can therefore be used in various sizes and shapes.

- It can be supplied in the form of rolls, making it cost effective and suitable for mass production.

By pasting it on an IC package, noise emission from the IC can be suppressed.

- When two circuit boards, or a circuit board and a component are connected using a cable, noise can be suppressed by pasting it on the surface of the cable.

- By placing it between circuit boards, the effect of the noise emission from one circuit board to the other circuit board can be reduced.

- By pasting it on the housing, the noise emission from the housing can be suppressed so that it does leak out.

Principle of Flexield

Flexield absorbs the energy of the emitted noise and converts it to heat, and thereby suppresses the effect of noise emission. This principle is outlined below.

The permeability (μ) of the soft magnetic metal which is mixed in the plastic has a significant impact on the noise suppression characteristics of Flexield. Permeability is the rate of increase in the magnetic flux density (B) when a magnetic field (H) is applied on a magnetic substance. In other words, permeability is an index of the ease with which magnetic flux passes through a magnetic substance (ease of magnetization), and it is expressed by the equation below.

- μ=B/H

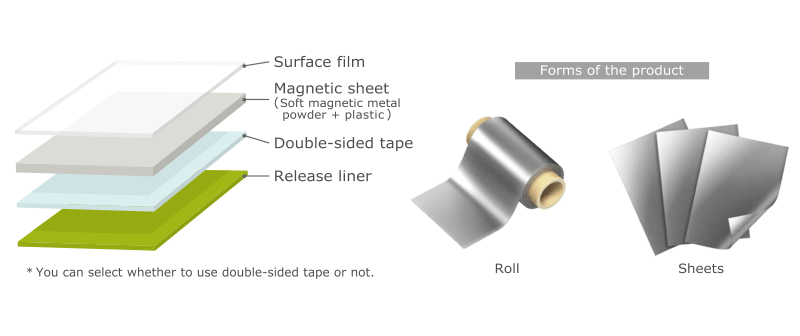

A soft magnetic substance is a magnetic substance which has high permeability and low coercivity. By applying an AC magnetic field, the direction of magnetization can be easily reversed, and hence it is put to a variety of uses such as in transformer cores. However, when an AC magnetic field has high frequency, the change in magnetic flux density (B) cannot keep pace with the changes in the magnetic field (H), resulting in a phase lag. If this phase lag is taken as δ, the permeability of the magnetic substance in the presence of alternating current is represented by the following complex notation.

- μ=μ'-jμ''=|μ|cosδ-j|μ|sinδ

μ' is known as the real part of complex permeability, while μ'' is known as the imaginary part. If δ=0, it represents the permeability of direct current, but as the frequency increases in the presence of alternating current, δ also increases, and the permeability drops. The real part μ', imaginary part μ'', and phase lag δ in complex permeability have the following relationship.

- μ''/μ'=tanδ

tanδ is known as the loss factor. In the transformer core, the smaller the value of tanδ, the smaller the loss is, which means that the core material is excellent, but Flexield proactively uses this loss and suppresses noise. Figure 3 is a schematic graph which shows the general trend in the permeability - frequency characteristics when an AC magnetic field is applied. In the region with low frequency, the real part μ' of complex permeability is dominant. However, when the frequency increases, the change in magnetic flux density cannot keep pace with the changes in the magnetic field, and in the end, it causes magnetic resonance (Magnetic domain wall resonance, rotational magnetization resonance, etc.), which leads to a sudden drop in the real part μ' of complex permeability, with a corresponding rise in the imaginary part μ''.

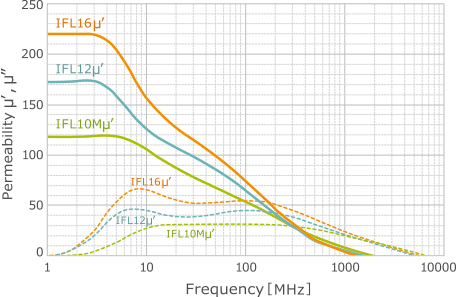

Permeability - frequency characteristics of the IFL series

The real part μ' of complex permeability is a value which expresses the ease of establishing magnetic flux, and when it is pasted on an antenna, it has the effect of extending the communication distance. On the other hand, the imaginary part μ'' is a value that shows the magnitude of the magnetic loss, or in other words, the magnitude of the noise absorption effect, and the soft magnetic metal contained in Flexield absorbs the noise component depending on the permeability of this imaginary part, and suppresses it by converting it to heat. Hence, the requirement from Flexield as a noise suppression sheet is that it should have a wide frequency range from low frequency to high frequency, and that a large part of the complex permeability should be the imaginary part μ''. Incidentally, in the magnetic sheet for RFID offered by TDK as a different type of Flexield for noise suppression (to improve the reception sensitivity of the reader/writer in RFID systems), the real part μ' is required to be large, and the imaginary part μ'' is required to be small for the usage frequency of 13.56 MHz. Thus, the required characteristics vary depending on the application. Figure 5 shows the permeability - frequency characteristics of the IFL series Flexield for noise suppression.

Various products in the IFL series and magnetic sheet thickness

The performance of a noise suppression sheet is determined by the product of the imaginary part μ'' of the complex permeability and the thickness. Generally, as the permeability of the material becomes higher, the imaginary part μ'' of the complex permeability also tends to increase. Therefore, to meet the need to make noise suppression sheets thinner, material with higher permeability is required.

Figure 5: Various products in the IFL series Flexield and magnetic sheet thickness

Manufacturing method of Flexield

There are two manufacturing method of noise suppression sheets. One is the dry method of using soft magnetic metal powder (flat powder) mixed with plastic as the raw material, and pressing it using a calender roll to make sheets. The other is the wet method of coating the film with a solution made by mixing soft magnetic metal powder with plastic and a solvent. The IFL series Flexield from TDK uses the wet method which employs coating technologies developed for magnetic tape, optical disks, and other electronic components.

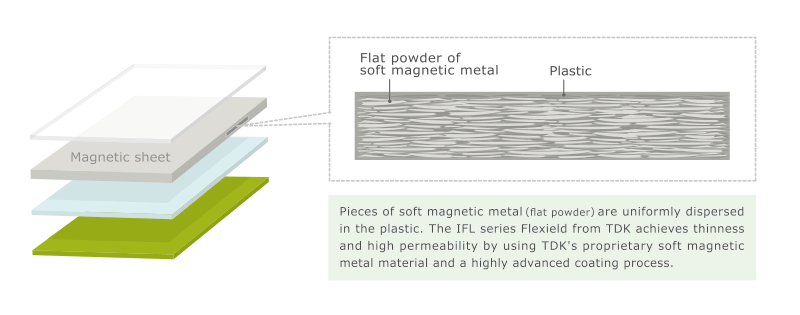

The wet coating method is a manufacturing method which is suitable for making the magnetic sheets thinner, but very highly advanced technology is required to uniformly disperse fine powder of soft magnetic metal in plastic, and to coat the solution along the surface of the sheet. Figure 6 shows the schematic diagram of the cross-sectional structure of a magnetic sheet. Each grain of soft magnetic metal powder is encased in plastic to retain its insulated state, and arranged corresponding to the orientation of the magnetic field to form a layer on the surface of the sheet.

The thickness of the soft magnetic metal powder also affects the characteristics of the magnetic sheet. In a conductor through which alternating current flows, as the frequency rises, current gets concentrated on the surface of the conductor. This is known as the skin effect, and the depth at which the current flows is known as the skin depth. As described earlier, the imaginary part μ'' of complex permeability represents the noise absorption effectiveness of the magnetic sheet. If the thickness of the soft magnetic metal layer used in the magnetic sheet is less than the skin depth, the value of the imaginary part μ'' increases. Hence, by controlling the thickness and arrangement of the soft magnetic metal layer, a magnetic sheet can be obtained with the desired permeability - frequency characteristics. The IFL series Flexield from TDK offers thin suppression sheets with high permeability by using TDK's proprietary soft magnetic metal material in which the real part μ' and imaginary part μ'' have been optimally controlled and by using a process which achieves excellent dispersion and orientation.

Figure 6: Cross-sectional structure (schematic diagram) of a magnetic sheet

New product "IFL series with a metal layer hybrid type"

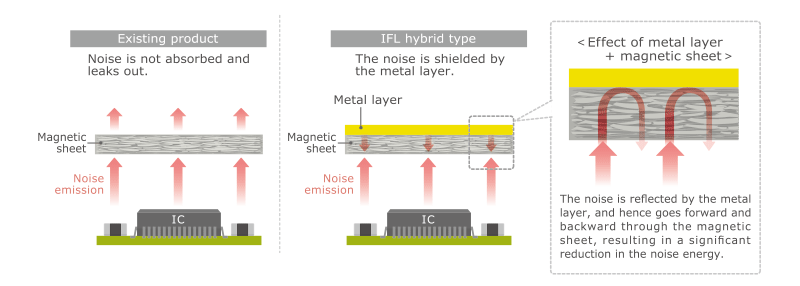

TDK presents a new product "hybrid type (magnetic layer+conductive layer)" with a metal layer for which mass production commenced in 2016. The hybrid type is a new type of noise suppression sheet which uses a metal layer instead of the surface film component in the existing product.

With the existing type of noise suppression sheet, even though the magnetic sheet absorbs the emission noise which passes through it, the noise which is not completely absorbed passes through the magnetic sheet and leaks out. This problem is solved by the newly developed IFL series hybrid type. As shown in Figure 7, noise which is not absorbed by the magnetic sheet is shielded by the metal layer, and the noise which is reflected by the metal layer is once again absorbed by the magnetic sheet. In other words, since the incident noise is absorbed by the thickness of the magnetic sheet on the onward path as well as the return path, the result is a significant reduction in the noise energy. In smartphones highly integrating a large number of electronic components, this can reduce the noise emission inside the housing, and hence it is also an effective solution to the problem known as "self-poisoning".

Figure 7: Function of the metal layer in the IFL series hybrid type

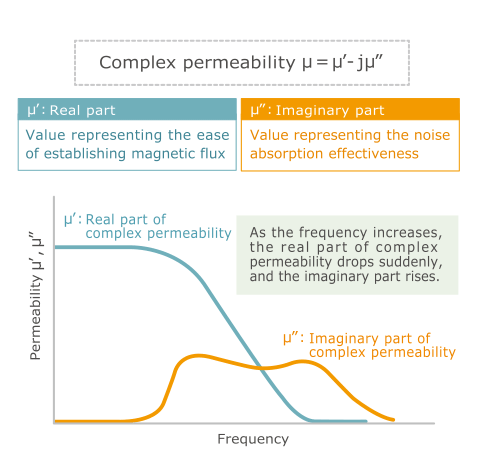

Figure 8 is an example of near electromagnetic field analysis using DDR memory as the equipment under test (EUT) in order to show the effectiveness of the IFL series hybrid type.

The area with high noise level is shown in red, while the area with low noise level is shown in blue. In the existing products, there is noise leakage, but in the IFL series, noise is almost completely suppressed. The noise shielding effect of the metal layer is clearly visible.

Figure 8: Noise suppression effectiveness of the IFL series hybrid type