Ferrite material N95 boosts the efficiency of power supplies

Minimizing losses

The new N95 ferrite material from EPCOS significantly reduces power transformer losses in switch-mode power supplies. Their efficiency can be greatly increased, especially when operating under no load or fractional load.

Power converters are developed to operate optimally, i.e. with maximum efficiency, at a defined operating temperature. As the winding losses depend on the square of the current and thus on the load, they are significantly reduced at low loads. As the load decreases, the temperature drops, so does the specific resistance of the windings, which also contributes to reducing the winding losses.

In contrast, the losses in power ferrites increase with decreasing temperature at a fixed voltage and frequency. That is why ferrite cores contribute primarily to the losses of the power converters at low loads or no-load.

For the N87 and N97 materials, the loss minimum is close to 100 °C, which is typical for power ferrites. Of the two materials, N97 has lower losses and its curve characteristic is similar to that of N87. However, the loss curve of the N95 material is lower and shows a relatively flat characteristic over a broad temperature range between 25 °C and 100 °C.

Core loss, winding loss and thermal resistance

- The frequency and flux density amplitude remain constant.

- The output voltage remains unchanged with load variation; the output current drops linearly with a fractional load.

- The power converter has a linear regulation over the entire load range from no load to full load.

- The duty cycle changes to compensate the effect due to regulation.

-

The thermal resistance is linear and remains constant as the ambient temperature changes.

At a transition to a lower ambient temperature of 30 °C, the slope of the thermal resistance curve is unchanged, but the operating point shifts to P2. In this case, the changeover to cooler surroundings hardly affects the transformer losses at all.

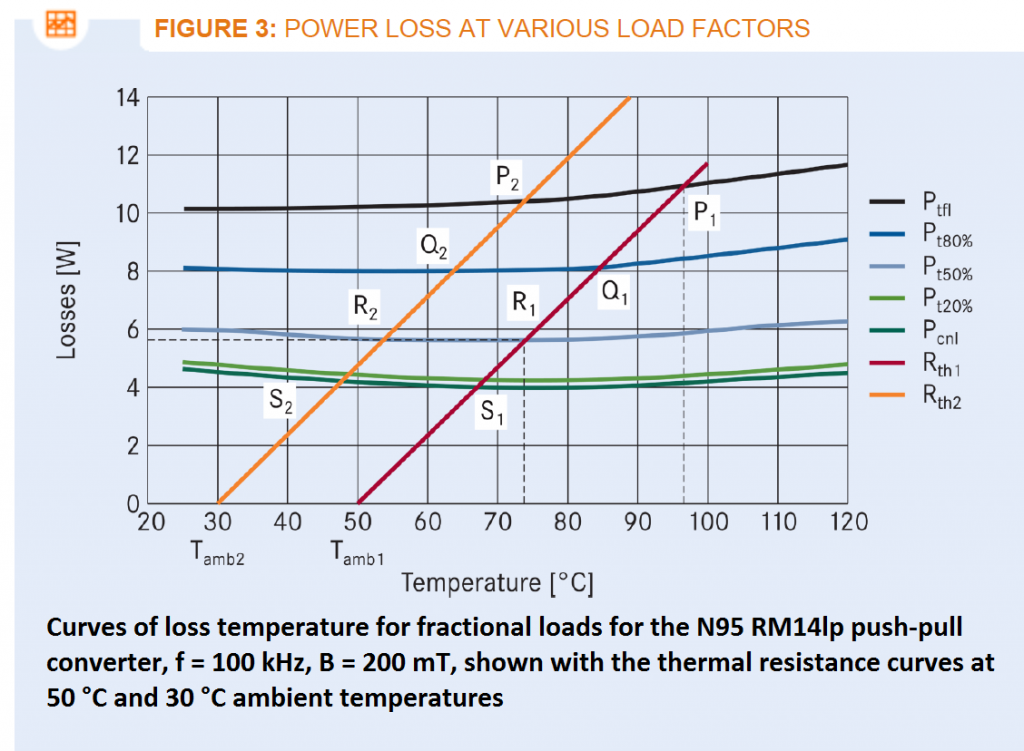

The curves of the transformer loss temperature (Fig. 3) at full load (Ptfl), 80 percent load (Pt80%), 50 percent load (Pt50%), 20 percent load (Pt20%) and no load (Pcnl) can be shown using the simplified model. The selected ferrite core is a low-profile RM14 (RM14lp) and the power ferrite material is N95. The power converter operates in push-pull mode, the duty cycle is standardized to unity at full load, the frequency is 100 kHz, the amplitude of the flux density is 200 mT, the ambient temperature is 50 °C and the temperature rise at full load is 50 °C. The regulation of the transformer between no load and full load is 7.5 percent. The transformer operates with maximum efficiency under the specified conditions.The throughput of the power converter is 756 W.

The operating points for full load, 80 percent load, 50 percent load and no-load are P1, Q1, R1, S1 for an ambient temperature of 50 °C, and P2, Q2, R2, S2 for an ambient temperature of 30 °C. The change of loss and temperature rise at fractional load can be determined from these curves. The point R1 on the curve yields an operating point at 50 percent load and an ambient temperature of 50 °C. The transformer losses are 5.55 W at an operating temperature of 73 °C.

Fig. 4 shows the potential savings achieved by replacing a conventional N87-RM14lp core by the materials N97 and N95. The loss reduction results in a direct energy saving: assuming that the average load at the power converter is 50 percent at an ambient temperature of 50 °C (point R1 in Fig. 3), the annual energy saving in 1000 of these converters is 11 400 kWh when N87 is replaced by N95 and 6100 kWh when it is replaced by N97. At an ambient temperature of 30 °C (point R2 in Fig. 3), savings of as much as 17 500 kWh are achieved when N87 is replaced by N95 and 5500 kWh when it is replaced by N97. Although the savings earned by N97 between 90 percent and full load are greater than those for N95 at an ambient temperature of 50 °C, the N95 material unequivocally exhibits the better savings at all loads at an ambient of 30 °C.

Less air-conditioning required

The energy saving at a low ambient temperature is greater with N95 than with N97. Temperature rise plays asignificant role in the energy savings, as the power supplies for server applications are in most cases located in air-conditioned surroundings. A lower temperature rise thus brings additional indirect energy savings. The power requirement for a conventional air-conditioning unit is about 3.5 kW per ton of treated air, and increases proportionally with the rise in temperature. With a power converter efficiency of 90 percent, the transformer alone can consume about 15 percent of the power required by the air-conditioning unit, corresponding to about 550 W per ton of air.

The energy saved by changing over from N87 to N95 is 830 kWh per ton of air/hour in the air-conditioning unit alone per annum – taking the pressure significantly off the environment.